With the above details, first-time consumers will have the ability to understand which valve will certainly appropriate for their commercial applications. It is always a great suggestion to get in touch with a shutoff vendor prior to making a choice. Relevant Posts Comprehending Industrial Control Valves and also their Types was last customized: July 12th, 2017 by.

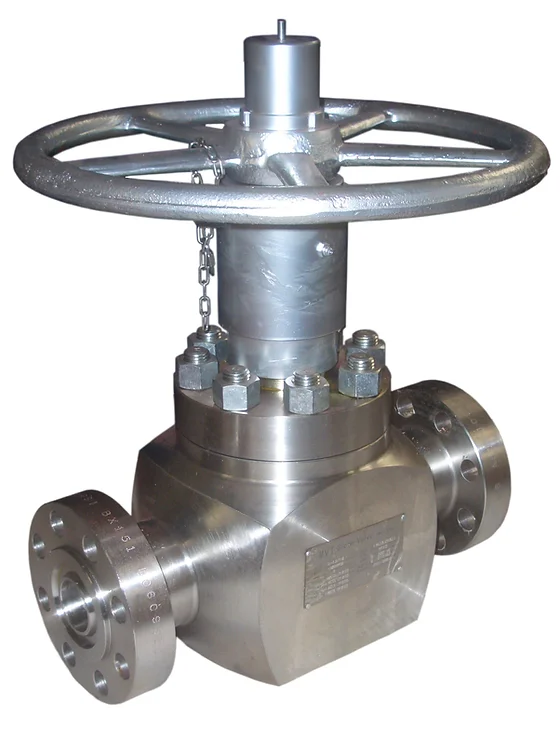

Worldwide Pipe distributes a large range of valve items from various makers. We have your option for your most important applications. What is an Industrial Shutoff? An industrial valve is a tool utilized to regulate the flow of liquid, gas, or slurries. Shutoffs are connected to pipes, and also they are recognized as the regulatory authority within a piping system.

Component I concentrates on shutoffs as tools, discovering exactly how they work and the main types frequently utilized in the Oil & Gas industry. Module II was designed to provide a broader view of the different supplementary procedures that border a shutoff application, such vendor auditing and model screening.

The Valve Accessories Statements

In this post, I will certainly give an overview of the most famous shutoff failures and also exactly how it can be feasible to stop or minimize the regularity of such troubles. In any case and also however the application, numerous shutoff users experiencing comparable issues.

Speaking about "valve failings" we naturally think of; Seat leakage, packing leak or a valve obtaining obstructed in open or closed setting. Here it is extremely crucial to understand that such failures in most cases are just repercussions of errors made long prior to the shutoff starts to leakage. In my 25 years of traveling the world as well as going to Power Plants as well as Refineries, in even more than 80% of the situations, the shutoffs have been mistakenly picked in the beginning of a job.

Below is my list of the most prominent factors for shutoff failings: Put on of the elastomers, seats, seals, and gaskets Use of the valve stem Cavitation Temperatures or pressures outside the made operating criteria, specifically unforeseen stress peaks in the pipe (usual error made is to develop valves to operating conditions and not style problems) Wrongly selected actuators (for example to much pressure on the seat while closing) Foreign particles in the pipeline (for example not enough Blow-Out after welding, or missing filters) Product incompatibility with the item being processed ending up in corrosion Wrong assembly, setup, or upkeep treatments executed on valve The initial two factors, even with a shutoff chosen properly, sadly, there is the reality that every elastomer, seat, gasket, ball, and so on

Considering the trouble of the application (for instance high temperatures/pressures, abrasive mediums, high rates) the failure of these components after a particular time of use, can be taken into consideration as "normal".

An intriguing factor is the issue. I have actually been included over the years in many situations of failures of Swing Examine Shutoffs. In some cases unsubstantiated, but there are people outside mounting a Swing Examine Shutoff upside-down or in the wrong direction! One more very typical problem with Swing Inspect Shutoffs (as well as likewise various other kinds of Check Shutoffs) is that during installment it has actually not been taken into consideration that there need to be a certain range from a pipe joint to the shutoff, or from a pump electrical outlet to the valve.

The smart Trick of Flush Tank Valve That Nobody is Talking About

Investment in brand-new technologies which can minimize failures is possibly the most significant obstacle of the shutoff industry over the following years. And also the requirement to utilize the valve to choose the proper valve to open or change the rate of the interior of the pipeline. Now, on the market, consisting of the most typically made use of valves such as: Ball shutoff structure is composed of a rounded ball as well as an opening via the round.